Table Of Content

Adjusting welding parameters and using suitable filler metals can also help avoid burn-through in welds. Shielding gas is used in certain welding processes, such as gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW), to protect the weld zone from atmospheric contamination. The choice of shielding gas depends on factors such as the welding process, the base metal, and the desired weld properties.

Donate to the AWS Foundation

Turning raw materials like sheet metal into usable products, components, and machinery would not be possible without good weld design. When designing products that require welding, the designer should consider very early on in the project the implications of the choice of welding process and how the component will be made. Welding can largely be described as a special process and the choice of welding process for a particular job can be difficult without expert knowledge.

Designer 2 Piece Sets: Elevating Your Wardrobe with Style and Sophistication

Yaheetech 3-Tier Welding Cart Review - Forestry.com

Yaheetech 3-Tier Welding Cart Review.

Posted: Thu, 21 Mar 2024 07:00:00 GMT [source]

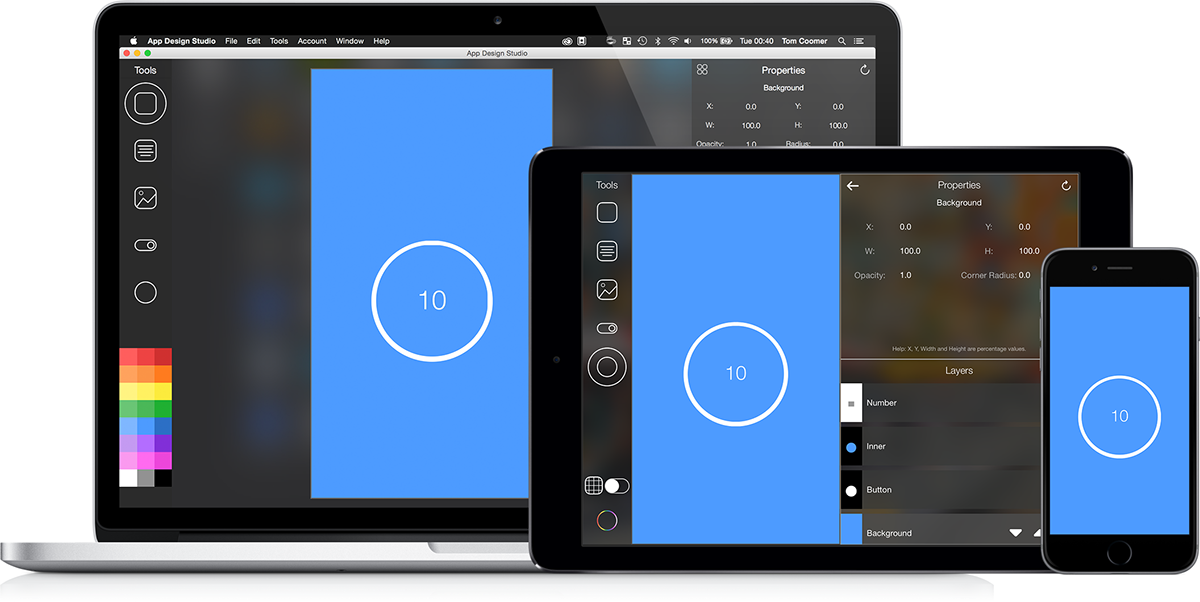

Users can work with complete confidence knowing that all their files are stored securely on the cloud. Automatic updating ensures your team will always view the latest version of a project. Access to files can be restricted so only authorized persons can view entire projects.

Importance Of Material Selection In Weld Design

It involves principles, procedures, and processes to ensure that welds have the desired shape, strength, ductility, and other qualities. Before welding, it is essential to clean the base metal to remove any contaminants that can affect the quality of the weld. Contaminants such as rust, oil, grease, and paint can lead to porosity, lack of fusion, or other defects.

For example, processes like gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW) provide precise control over heat input, resulting in stronger welds. On the other hand, processes like shielded metal arc welding (SMAW) may introduce more variability in heat input, potentially affecting joint strength. Welding designs encompass various types to meet different quality standards.

Good weld design is reliant on the skills of the mechanical design engineer or mechanical designer and on the power of the programs they use. Weld design experts turn to respected developers such as Dassault Systèmes for effective CAD solutions. The range of CATIA mechanical design programs combined with the 3DEXPERIENCE platform gives professionals the tools they need to effectively create, collaborate, and innovate.

Weld Design Optimization for Specific Applications

Fourteen-inch metal-cutting saws like this, outfitted with an abrasive blade, cost $100 to $200. A large metal-cutting saw with carbide teeth cuts metal like butter and with less burrs, but it will set you back more than $250. Never put a carbide-tooth blade on an abrasive saw because this saw runs at twice the rpm, a speed that could destroy the blade or worse. Miter saws designed to cut wood also spin too fast for metal-cutting blades, and since their motors aren’t sealed, the metal chips and shavings can destroy the motor. Weld in design space refers to the process of combining multiple shapes to form a unified and customized image by eliminating any overlapping cut lines.

Each symbol represents a specific type of weld and provides information about the weld size, length, and other relevant dimensions. Welding symbols are a universal language used to communicate weld design requirements. Understandingwelding symbols is essential for ensuring compliance and accurately executing weld designs as per specifications.

Therefore, proper surface preparation and the use of appropriate coatings or corrosion-resistant alloys may be necessary to ensure long-term durability. GMAW offers several advantages, including high deposition rates, good control over weld bead appearance, and minimal post-weld cleaning. It is particularly well-suited for applications that require high productivity and aesthetic welds. However, GMAW may not be suitable for welding in tight spaces or vertical or overhead positions, as the molten weld pool tends to be more fluid.

Butt Joint, Tee Joint, Lap Joint, Corner Joint, Edge Joint, each of these joints has a specific purpose and is designed to optimize the strength and durability of the weld design. The CATIA suite works in conjunction with the powerful 3DEXPERIENCE platform. This innovative cloud based solution allows mechanical designers and engineers the ability to easily collaborate and communicate and safely store their files in the cloud using any device.

Compliance with contractual obligations and adherence to established policies are essential factors in maintaining quality assurance. Meeting deadlines and complying with noise regulations, for example, are critical in creating a safe and efficient work environment while achieving customer satisfaction. Bob McReynolds, P.E., has worked as a welding & metallurgical engineer in the power, defense and infrastructure industries since 1993. He is licensed as a Professional Engineer and is an AWS Certified Welding Engineer and Certified Welding Inspector.

Welders use oxyacetylene welding machines for the fabrication of metal parts, structures, and machinery. Safely creating a weld that is robust requires considerable skill on the part of the welder as well as the weld designer. CATIA from Dassault Systèmes has been used by engineers and designers in specialized fields such as the automotive and aeronautical industries for decades. CATIA weld design software is flexible, reliable, and powerful enough to deal with assemblies of any size. Welding is a crucial process for product design, construction, and manufacturing.

Fillet welds sizes should be specified preferably by referring to the throat thickness 'a' although the leg length 'z' is often used and can be easier to measure during weld inspection. Conventionally, the leg lengths are regarded as being of equal dimensions, the weld forming an isosceles triangle in cross section. Welding design is the process of planning and creating the layout, dimensions, and specifications for a welded structure or component. Stress in welding joint is defined as load (or force) divided by the cross-sectional area (CSA) of the component subjected to load. We are the experts in using Pro/ENGINEER (now called Creo Parametric) for machine design process.

No comments:

Post a Comment